Today’s automotive industry operates in a rapidly changing world, requiring companies and governments to clearly identify technological, social, and geopolitical changes impacting the industry and markets. “The global automotive industry stands amid a period of profound uncertainty,” noted Andrew Fellows, head of automotive and mobility at Star Global.

In a May report titled “Global Automotive Industry Outlook: An East Meets West Perspective,” Star Global outlines the latest manufacturing and consumer demand trends, as well as geopolitical influences.

Emerging east

According to the report, Asian countries’ emergence as major auto manufacturing destinations is “no accident. It is the result of … decades of strategic policymaking, aggressive investment in research and development, and supply chain mastery.”

Most strategies focused on leapfrogging established car brands in Europe and the United States. “While Japan, Germany and the U.S. focused on refining internal combustion engine (ICE) technology, China leapfrogged into EV innovation and market expansion with double-digit year-over-year growth.”

Sustaining these leaps is “the power of state policy,” where government-led investments, private-sector support and awareness are aligned toward the predetermined state vision. Their toolbox includes bespoke initiatives, tax breaks for buying locally made cars, the factories that produce them, and importers of a particular type of car, the report said.

These governments and domestic public and private carmakers also heavily invest in infrastructure for the cars they promote and manufacture, even before they prove commercially viable, the report said. One example is EVs, where carmakers and governments built charging stations before EV awareness and sales boomed.

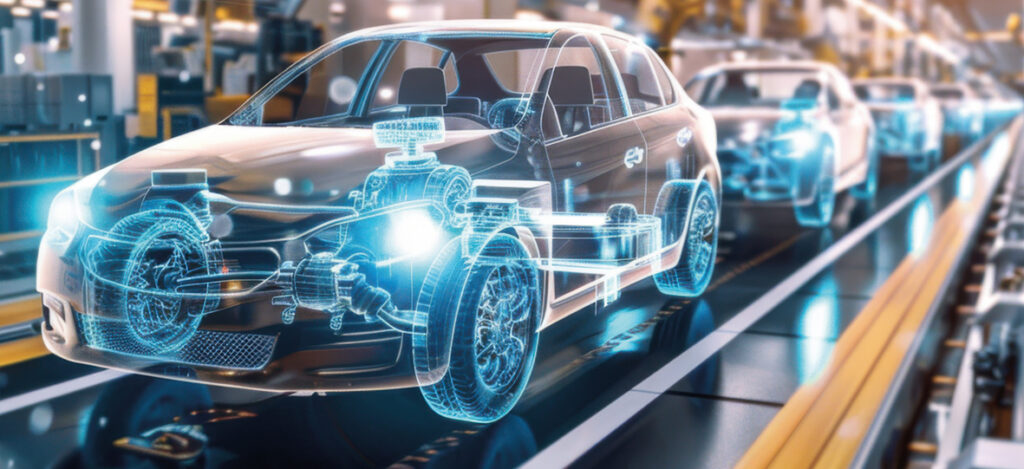

Another strategy Asian carmakers adopt is acquiring feeder companies, especially battery suppliers. “Battery technology is a key differentiator – it is the single most critical component in an electric vehicle, influencing cost, performance, driving range, charging speed, and overall efficiency,” the report said. “Batteries account for 30% [to] 50% of an EV’s total cost, making them the most expensive part of production.”

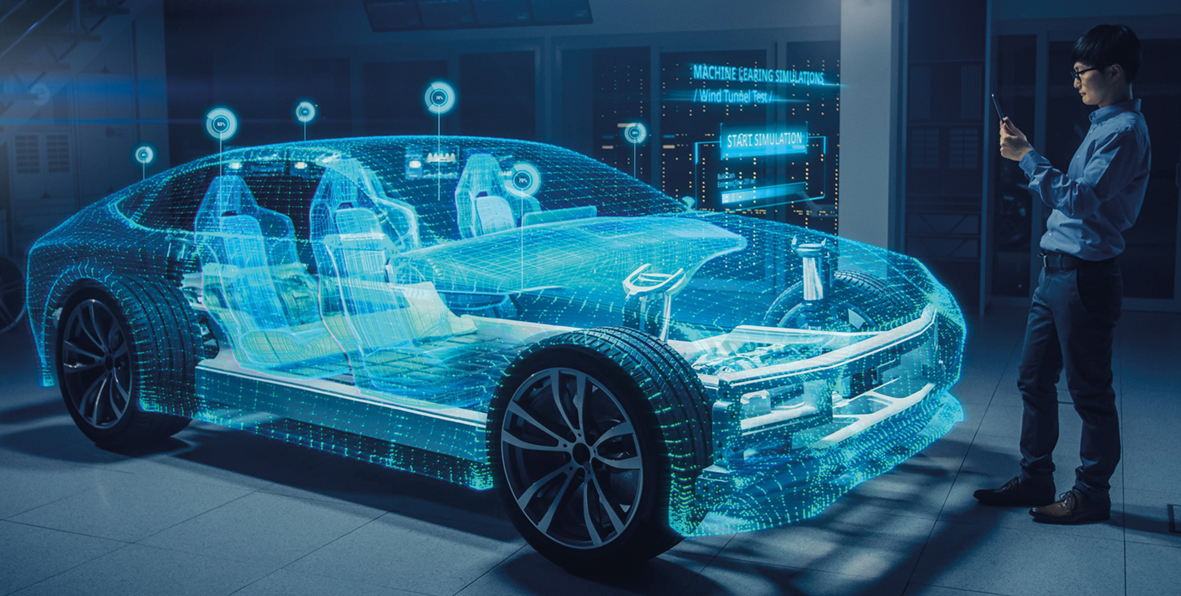

Within their factories, Asian carmakers focus on “digital-first manufacturing [by] deploying … software updates every 45 days, [while] legacy manufacturers often go 12 to 18 months between software updates.” The faster update schedule “enables more frequent product improvements and feature enhancements, creating a continuously evolving ownership experience,” the report said.

Limiting growth

Governments building an auto industry face common challenges. First is “government policy reinforcement.” The report said the problem isn’t announcing auto-favorable initiatives, but implementation often lags.

The second is “cultural and operational barriers to innovation,” the report said. “Mindset delays time-to-market for digital features. Younger leadership may accelerate change, but generational shifts in management remain slow.”

Third is “the quality paradox,” the report said. “Automakers equate quality with defect-free engineering [that] clashes with the iterative ‘fail fast’ approach of digital-native firms. While this ensures reliability, it stifles experimentation.”

New preferences, risks

Another critical factor facing auto manufacturers is “ownership models are changing,” the report said. “Younger generations are less attached to traditional car ownership, especially in urban areas.”

In Europe, “a surge in car-sharing services, both station-based [like conventional public transportation] and free-floating fleets [such as ride-hailing apps],” is evident. Around a third of those surveyed said they “would consider a car subscription over buying,” the report said. “This number indicates a growing preference for flexibility, convenience, and cost predictability among younger generations.”

Further fueling that shift is that cars have become less affordable, especially EVs, which young buyers prefer as their awareness of environmental issues increases. “Prices remain a key barrier to adoption … with nearly three-quarters of consumers surveyed,’ the report said.

That led automakers to “invest in mobility services,” the report said. In 2024, Stellantis completed the integration of Share Now, a car-sharing business. Meanwhile, BMW offers the car-sharing service Drive Now and Daimler has Car2Go.

That is risky as it “threatens to cannibalize traditional sales and challenges [carmakers] to manage fleets and residual values,” the report said. “Access is rivaling ownership … Young consumers value convenience and cost transparency while [carmakers] evidently prefer long-term ownership to maintain their traditional business model.”

For those still buying cars, automakers are starting to “sell directly to consumers (often online) at a fixed price, with dealerships becoming delivery and service agents,” the report said. “Mercedes-Benz and Volkswagen Group have started implementing this in Europe.”

That strategy caters to “consumers’ desire for a more streamlined, haggle-free buying experience – much like buying a phone,” the report said. “It also allows [car] brands to maintain a direct digital relationship with customers throughout the vehicle’s lifecycle, which is vital for subscriptions … and brand loyalty.”

Rethinking supply chains

Another business change is that “automakers are forced to rethink how globalized versus regionalized their operations should be,” the report said. “Past decades were marked by globalization – complex supply chains stretching to the cheapest sources, heavy reliance on China (both as a market and supplier) and centralized production of key components.”

Today, carmakers prioritize “centralization … of technology platforms within holding groups and through joint ventures [to] achieve scale and cost-efficiency in EVs, which have heavy upfront R&D costs.”

This means less focus on economies of scale and low-cost destinations in favor of more mergers, acquisitions and partnerships among major automakers and startups with a foothold in the EV market. In the long term, “it’s conceivable that not all current brands will survive independently,” the report noted.

Such consolidation could also occur among suppliers, including battery suppliers, chipmakers, and software firms partnering with automakers to secure know-how.

For countries building an auto industry, there are options. “Foreign competition has ended the comfort zone for [European] automakers,” the report said. “The once assumed premium for [European] engineering is no longer a given in places like Asia, as local brands are investing more in the mid-market range to match or even exceed Western quality and innovation.”

Geopolitical playbook

The U.S. administration’s increasingly protectionist policies, raising tariffs on foreign-made cars and parts, are upending the global market. “Saying the … automotive industry is standing at a critical juncture is an understatement,” the report said.

Before April’s tariff hikes, the automotive industry was “marked by steady growth, increased electrification and an integrated … production system,” the report said. “The industry was navigating both opportunities and challenges as it moved toward a more electrified future.”

Raising barriers in “the world’s second-largest automotive market in sales and production … is forcing both U.S. automakers and those selling to the world’s largest economy to rethink their supply chains, manufacturing, go-to market strategies and long-term strategies.”

The big issue cars face when made outside the United States is that protectionist policies might succeed. “This could mean reshoring certain component production — for example, moving electronics supply from a Chinese plant to an American one, where feasible, or pressuring suppliers to add U.S. capacity,” the report said. “We are already observing some reshoring due to incentives and earlier trade tensions, but not on the scale the [U.S.] government expects.”

Choose carefully

Ultimately, car buyers will likely choose locally manufactured automobiles over imports, meaning governments have to select the types of vehicles made in the country to realize their vision.

In Japan, “EV sales … in 2024 recorded only 59,736 units sold, which puts Japan’s EV adoption rate below 2% of its total vehicle sales,” the report said. “This deceleration is partly attributed to Japan’s strategic focus on hydrogen fuel cell vehicles over battery electric vehicles.”

China, the IEA said, accounted for more than 70% of global production in 2024. The China Association of Automobile Manufacturers reported that from January to August, local EVs accounted for 51% of the country’s total vehicle sales.

To attract FDI, countries building an auto industry should cater to the needs of global car brands. The report stressed carmakers are looking for local “data-driven supply chain resilience,” “intelligent, adaptive ecosystems,” and systems that “dynamically sense and respond to market shifts.”